Over the last century, epic advances have been made in transportation technologies, however, not only are we still using primitive and environmentally harmful fuels and chemistries to propel our mass transit services we are taxing the electric grid to do so.

Conserving for the future means adopting technologies that will minimize power usage through improved efficiency and more accurate forecasting and maximize existing infrastructure.

Energy Storage System Rides the Rails

In the U.S. and around the world, electrically propelled subway rail trains and light rail vehicles (LRVs) use AC propulsion with induction traction motors and variable voltage, variable frequency drives (VFD).

Electric trains draw a huge amount of energy to accelerate away from the platform – the same peak demand used as 1,000 average U.S. homes. However, as deceleration occurs pulling into the next station, the train sheds significant amounts of energy to stop the train. Up to 90 percent of that braking energy can be recovered and used to launch the train from the station, reducing demand on the grid. If train stations can harvest the energy of incoming trains as they brake, they can re-cycle that same energy to launch the same train, or another train, as it leaves the station. That's the idea behind flywheels, providing clean and environmentally friendly energy storage.

Flywheel Energy

A flywheel system stores energy mechanically in the form of kinetic energy by spinning a mass at high speed. Electrical inputs spin the flywheel rotor and keep it spinning until called upon to release the stored energy. The amount of energy available and its duration is governed by the mass and speed of the flywheel. In a rotating flywheel, kinetic energy is a function of the rotational speed of the flywheel and the mass moment of inertia. The mass moment of inertia relates the mass and diameter of the flywheel. The kinetic energy of a high-speed flywheel takes advantage of the physics involved resulting in exponential amounts of stored energy for increases in the flywheel rotational speed.

Advantages to using flywheel technology when compared to chemical batteries:

- Response – it can promptly store huge bursts of energy, and equally rapidly return them

- Efficiency – charges/discharges are made with very small losses; as an electrical storage system a flywheel can have efficiencies over 97 percent

- Maintenance – flywheels do not require cooling nor do they pose the chemical recycling/maintenance issues of conventional batteries

- Lifespan – flywheels have a typical lifespan of about 20 years, while a lead-acid battery needs to be replaced every three to seven years (and even sooner for high cycle applications)

Flywheels are capable of millions of full charge and discharge cycles over the life of the system with no degradation in voltage, power, or storage – unlike batteries. Flywheel technology is also considered the only green technology of the storage technologies applicable to the rail market and in the energy storage market in general.

The return on investment for flywheels is evident – they require little maintenance, are self-protecting during emergencies and are highly efficient with very low waste energy during charging, discharging, and idling.

Energy Storage Technologies

Transit operators have evaluated and tested flywheels, super capacitors, and batteries for transit ESS application. Table 1 summarizes the advantages and obstacles for each. Flywheel demonstration projects in the transit industry include New York City Transit, London Underground, Paris, Lyon, and others. Both wayside and railcar demonstration projects are under way. The highest rated unit demonstrated to date is a 1 MW, 7 kWh flywheel energy storage system, and larger units are now under development.

Table 1: Energy storage comparison

Putting Flywheels to the Test

Recently, the Los Angeles County Metropolitan Transportation Authority (Metro) awarded a $3.6 million contract to install a Wayside Energy Storage Substation (WESS) at the L.A. Metro Red Line Westlake/MacArthur Park Station utilizing flywheel technology. The new WESS system will demonstrate how it can lower the cost of peak power demands, reduce energy consumption, decrease wasted energy and lower power demands to the utility during critical peak power usage. According to L.A. Metro’s project manager, Frank Castro, “Metro is committed to an extensive energy savings and sustainability program. In the last five years, two megawatts of photovoltaic energy-saving equipment has been already installed. The WESS Project alone, with its two megawatts of flywheel energy recycling power capacity, will double this number.”

Potentially, the benefits of the new WESS system could include the elimination of train slowdowns and stop/starts by correcting low voltage occurrences, an increase in system reliability through greater power capacity, as well as a redundancy in power source for adjacent substation outage or emergencies.

Another advantage to the WESS system is that it does not use onboard flywheels. Instead, the flywheels are used to store energy trackside at each station, meaning there are fewer limitations on size, and the weight of the device does not have to be transported.

At the Westlake and MacArthur Station on the LACTMA rail line, the flywheels will store 2 MW and fit into the existing electricity substation. The power storage unit consists of four modules, each containing a high-speed steel flywheel and a motor/generator. Each module is approximately 0.9m by 1.2m (3ft by 4ft).

And other transportation hubs are looking to follow suit. The future is where flywheels are not only installed in existing public transport systems, but designed into them from the start. One of the key advantages being that new systems can alternate between the placement of a substation and flywheel storage to reduce overall infrastructure cost, as there is no need to drop power lines every mile.

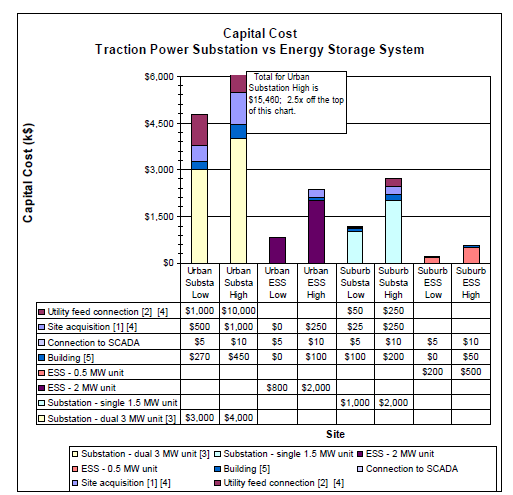

Traction Power Substation vs. Energy Storage System

Looking Ahead

Flywheel technology is ideally suited for electrified rail and subway systems, offering green, cost effective energy storage and recycling solutions. Not only can braking energy be captured and stored, but flywheel systems can also provide voltage support supplementing existing rail traction power substations. Metro transit agencies can benefit with improved performance, lower capital costs, and reduced energy usage.

Patrick T. McMullen is the Chief Technical Officer for VYCON. He has a BS, Mechanical Engineering, from the University of Notre Dame and holds an MBA from the University of Southern California. Patrick was a co-founder of Calnetix and has worked full time at VYCON since mid-2003. He has over 20 years of experience in the magnetic devices field for high speed equipment, with 14 years of experience in the magnetic bearing field. McMullen developed the original flywheel system concept while at Calnetix, where he served as vice president.